Views: 173 Author: Site Editor Publish Time: 2022-07-25 Origin: Site

Hydraulic cylinder design calculation steps

1.Find out the movement characteristics of the hydraulic cylinder and determine the form of the cylinder to be designed

All designs originate from demand, and the demand for product performance is the standard requirement to be met in the later design. The same is true for the design of the oil cylinder. Before the design of the oil cylinder, it is necessary to understand the application function requirements and realize the required functions in the later design.

There are many types of hydraulic cylinders, including piston type, plunger type, telescopic sleeve type,

According to the form of movement, it can be divided into reciprocating linear type and swing type

According to the function, it can be divided into double-acting and single-acting cylinders

Therefore, before determining what type of oil cylinder to use, you must figure out how you want the oil cylinder to operate, and determine the appropriate hydraulic oil cylinder form according to the set movement form and characteristics.

2. To further understand the operating conditions of the hydraulic cylinder

(1) The working conditions of the hydraulic cylinder, such as temperature and ambient humidity, are used to determine the anti-corrosion level and dust-proof level of the hydraulic cylinder.

(2) The required output, load status, stroke size, working system, etc. of the hydraulic cylinder are used to determine the size of the piston and piston rod of the hydraulic cylinder, check the ultimate strength of the hydraulic cylinder and calculate the fatigue life

(3) The working pressure and flow rate selected by the hydraulic system; assist in determining the important dimensions of the hydraulic cylinder piston and piston rod.

3. Select the rated pressure of the hydraulic system, calculate the piston cross-sectional area of the hydraulic cylinder according to the hydraulic cylinder output required by the host, and round it according to the standard series in the national standard.

4. After the material of each main component is selected, the wall thickness of the hydraulic cylinder, the diameter of the hydraulic piston rod, etc. can be calculated according to the output requirements of the hydraulic cylinder and the material strength, etc.

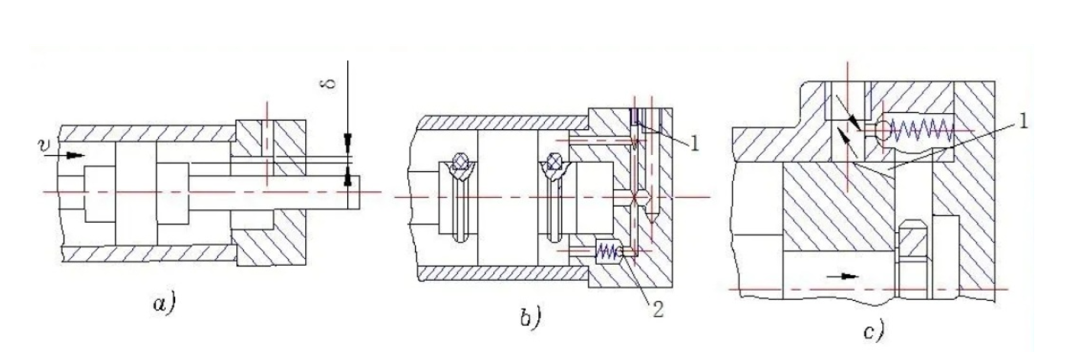

5. Determine the structure of the hydraulic cylinder and the connection form of the front and rear covers according to the connection interface with the host and the installation space.

6. Determine the sealing form of the hydraulic cylinder according to the hydraulic oil pressure, the operating temperature range of the hydraulic cylinder, and whether there is dust.

Hydraulic cylinder seal design selection

7. According to the operating load and control conditions of the hydraulic cylinder, the hydraulic buffer should be reasonably designed. The reasonable buffer design can reduce the impact load and avoid the early damage of the hydraulic cylinder.