Views: 308 Author: Site Editor Publish Time: 2023-03-03 Origin: Site

Main causes of hydraulic valve failure and corresponding preventive measures

Hydraulic valve is an indispensable hydraulic element in almost all hydraulic systems. Hydraulic valve plays a role in controlling the speed, direction and pressure of the actuating element in the hydraulic system. The failure of hydraulic valve will have a huge impact on the entire hydraulic system, and even directly lead to the failure of the hydraulic system or the occurrence of machine damage accidents. Today, taking the relatively concentrated phenomenon of hydraulic valve failure as the starting point, the causes of hydraulic valve failure are briefly summarized, I hope it can provide you with some reference.

Failure reason of hydraulic valve

1) Mechanical failure

(1) Wear: the friction between the moving pairs of the hydraulic valve core, valve sleeve, valve body and other mechanical parts constantly occurs during use, which makes the size, shape and surface quality of the parts change and fail.

(2) Fatigue: When working under long-term variable load, the spring in the hydraulic valve will become soft, shorten the length of the spring or break the whole spring due to fatigue; The valve core and valve seat may also be cracked, peeled off or otherwise damaged due to fatigue. These may cause valve failure.

(3) Deformation: When the residual stress of the hydraulic valve parts in the process of processing and the external load stress in the process of use exceed the yield strength of the part material, the parts will deform and fail to complete the normal function.

(4) Corrosion: The hydraulic oil is mixed with too much water or acidic substances, which will corrode the relevant parts in the hydraulic valve after a long time of use, making it lose its due accuracy and become invalid.

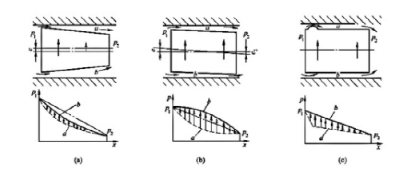

2) Hydraulic clamping

When the pressure oil flows through the cylindrical spool valve structure of the hydraulic valve, the radial unbalanced force acting on the valve core causes the valve core to jam, which is called "hydraulic clamping".

3) Hydraulic impact

The hydraulic system changes direction or closes the oil passage quickly, so that the oil flowing in the system suddenly changes direction or stops flowing, resulting in a sharp rise in pressure, forming a large pressure peak, namely hydraulic impact.

4) Cavitation

In the hydraulic system, the phenomenon of bubbles caused by pressure drop due to the change of liquid flow rate is called "cavitation". Cavitation and cavitation worsen the working performance of the hydraulic system and reduce its reliability.

2. Corresponding preventive measures

1) The mechanical failure of the hydraulic valve has a great relationship with the design of the valve and the processing of the parts, so the preventive measures we can take in maintenance are relatively limited

2) Improving the cleanliness of the hydraulic oil helps to reduce the sticking phenomenon of the valve core caused by impurities. When installing the slide valve, try to tighten the valve body threads according to the design requirements to avoid the sticking of the valve core due to stress deformation. Pay attention to the oil temperature of the hydraulic oil, and try to avoid the deformation caused by excessive temperature change. Because the gap between the valve core and the valve body is very small, a slight deformation may cause the operation to be blocked and blocked.

3) Under the condition of not affecting the rhythm, try to slow down the switching speed of the reversing valve. You can also add appropriate damping (throttle) to slow down the switching speed, so as to extend the switching time and reduce the impact. You can also increase the accumulator to absorb the impact and reduce the impact of the impact. Using hose instead of hard pipe can also play a role of cushioning to a certain extent

4) Reducing the air content in the hydraulic oil can greatly reduce the occurrence of cavitation. Therefore, it is necessary to pay attention to the sealing of the pump and the sealing of the joints in the pipeline to ensure that there is no leakage, reduce the probability of air mixing in the oil, and ensure that the oil suction pipeline is unblocked, ensure that the oil suction pressure is greater than the air separation pressure, and prevent water and other volatile substances from mixing in the oil.

To sum up, the mechanical failure of hydraulic valve is mainly related to the management and maintenance of hydraulic equipment in addition to processing and manufacturing factors, so don't wait until the hydraulic system can not work properly. Usually, more pre-judgment and pre-processing should be done to eliminate the equipment failure caused by hydraulic valve failure in the bud