| Availability: | |

|---|---|

| Quantity: | |

| hydraulic cylinder | telescopic hydraulic cylinder | cylinder hydraulic | manuli hydraulic cylinders | ryco hydraulic cylinders |

| mini hydraulic cylinders | hydraulic ram pump | double acting hydraulic cylinder | hydraulic press cylinder | double acting hydraulic cylinder |

| hydraulic jack | hydraulic bottle jack | jack hydraulic | hydraulic press | other hydraulic tools |

Quick Details

Warranty:1.5 years

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Brand Name:UNLE

Place of Origin:Shandong, China

Structure:Customized

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service.

Description

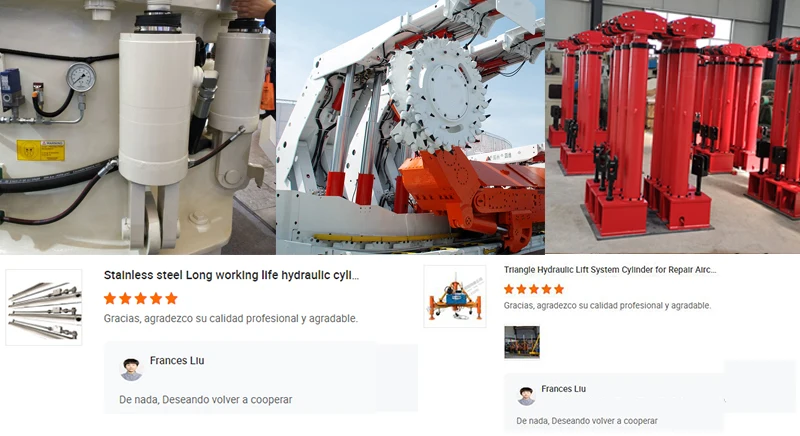

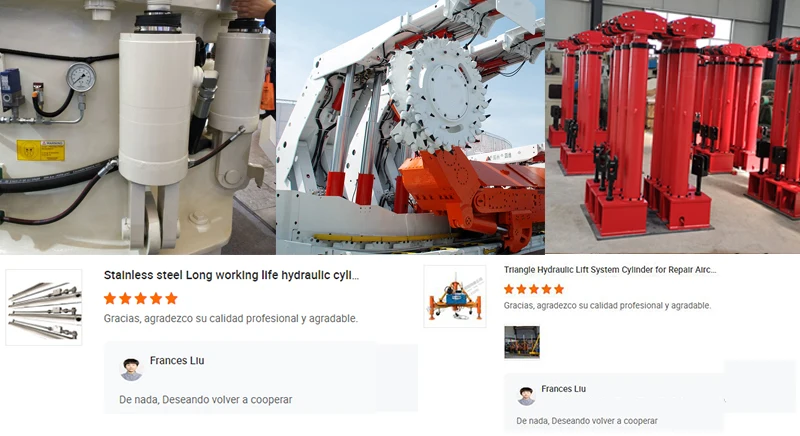

Self-elevating platform hydraulic lift system is powered by a separate hydraulic drive system to ensure that the legs are able to overcome the resistance of the soil, sand and the gravity of the lift platform , insert the legs into the seabed and lifting the entire platform. According to the platform lifting conditions, operating conditions, self-storage conditions, the calculation of weight of preloading conditions and the calculation of environmental load to determine the lifting system of the normal lifting capacity, preload lifting capacity, hull lifting speed. Offshore platform hydraulic lifting system design should meet the following functions: to ensure that the system has enough power to overcome the soil, sand and other resistance and the platform's own gravity, the pile body into the (pull away) the sea bed and platform movements; During the process, the hydraulic actuator will meet the requirements of a certain pitch stroke; the system is designed as a self-locking hydraulic system of the leg, in a variety of work and non- In the working state, the system can realize self-locking. Complete the platform lift by operating the computer or the central console .

The control system cooperates with the speed and position of the main cylinder, the upper pin cylinder and the lower pin cylinder (signal detection and logic judgment module) to perform precise control and detection accuracy of 1mm. At the same time, the system in accordance with the requirements of the hydraulic station, the electromagnetic valve to the logic control, real-time detection system pressure, level, oil temperature and filter status, and system failure diagnosis, alarm, processing. Each main cylinder is moved by a displacement sensor to detect the telescopic displacement of the cylinder. The displacement detection signal is transmitted to the controller through the control cable, and the control signal is sent to the hydraulic station and the hydraulic control module to make the control signal to control the pile and the hydraulic control module in order to realize the stable and reliable implementation of the pile, the pile, the pile and the pile action. Through the lateral position detection device and the longitudinal position detection device with the main cylinder on the displacement sensor can accurately know the working state of the upper and lower bolt, to prevent the plug inserted into the unexpected circumstances such as serious consequences .

Selling Units:

Single item

Single package size:

50X30X30 cm

Single gross weight:

100.000 kg

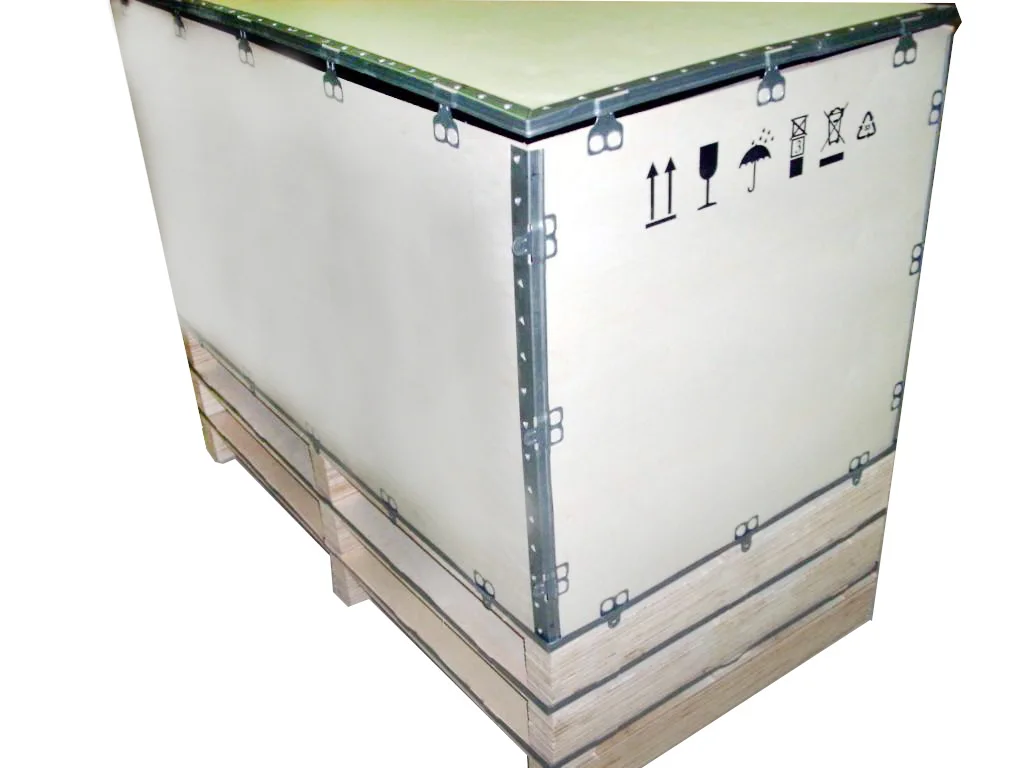

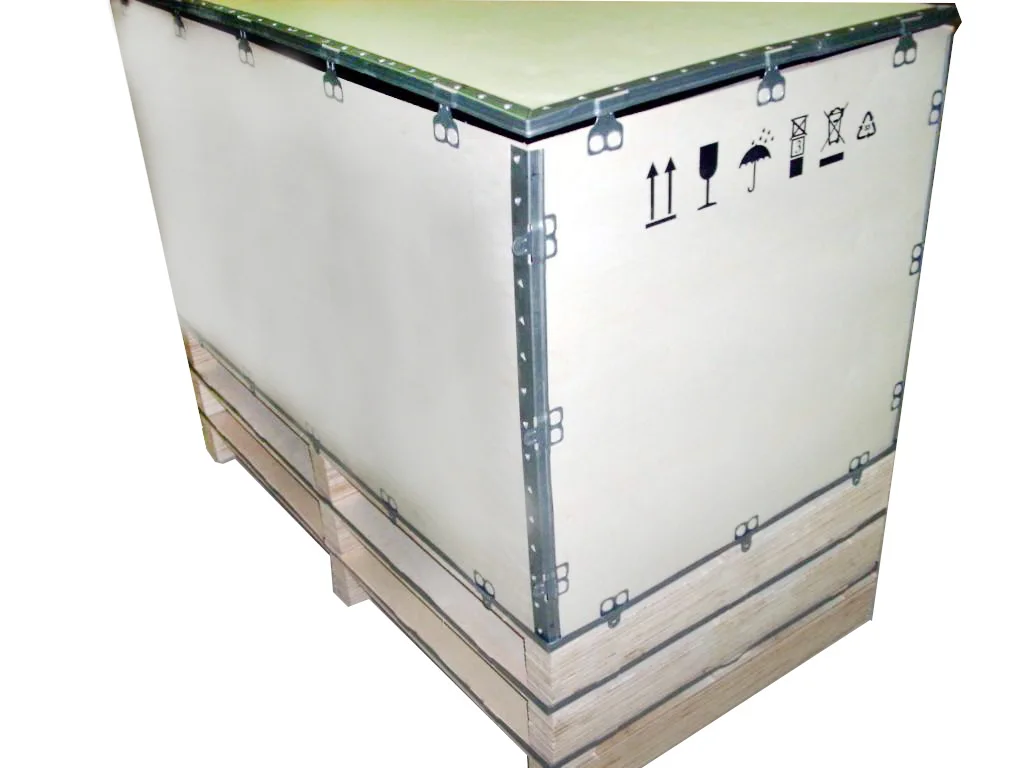

Package Type:

Carton box or wooden case

Picture Example:

Lead Time:

| Quantity(Sets) | 1 - 1000 | >1000 |

| Est. Time(days) | 30 | To be negotiated |

| hydraulic cylinder | telescopic hydraulic cylinder | cylinder hydraulic | manuli hydraulic cylinders | ryco hydraulic cylinders |

| mini hydraulic cylinders | hydraulic ram pump | double acting hydraulic cylinder | hydraulic press cylinder | double acting hydraulic cylinder |

| hydraulic jack | hydraulic bottle jack | jack hydraulic | hydraulic press | other hydraulic tools |

Quick Details

Warranty:1.5 years

After Warranty Service:Video technical support, Online support, Spare parts, Field maintenance and repair service

Brand Name:UNLE

Place of Origin:Shandong, China

Structure:Customized

After-sales Service Provided:Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service.

Description

Self-elevating platform hydraulic lift system is powered by a separate hydraulic drive system to ensure that the legs are able to overcome the resistance of the soil, sand and the gravity of the lift platform , insert the legs into the seabed and lifting the entire platform. According to the platform lifting conditions, operating conditions, self-storage conditions, the calculation of weight of preloading conditions and the calculation of environmental load to determine the lifting system of the normal lifting capacity, preload lifting capacity, hull lifting speed. Offshore platform hydraulic lifting system design should meet the following functions: to ensure that the system has enough power to overcome the soil, sand and other resistance and the platform's own gravity, the pile body into the (pull away) the sea bed and platform movements; During the process, the hydraulic actuator will meet the requirements of a certain pitch stroke; the system is designed as a self-locking hydraulic system of the leg, in a variety of work and non- In the working state, the system can realize self-locking. Complete the platform lift by operating the computer or the central console .

The control system cooperates with the speed and position of the main cylinder, the upper pin cylinder and the lower pin cylinder (signal detection and logic judgment module) to perform precise control and detection accuracy of 1mm. At the same time, the system in accordance with the requirements of the hydraulic station, the electromagnetic valve to the logic control, real-time detection system pressure, level, oil temperature and filter status, and system failure diagnosis, alarm, processing. Each main cylinder is moved by a displacement sensor to detect the telescopic displacement of the cylinder. The displacement detection signal is transmitted to the controller through the control cable, and the control signal is sent to the hydraulic station and the hydraulic control module to make the control signal to control the pile and the hydraulic control module in order to realize the stable and reliable implementation of the pile, the pile, the pile and the pile action. Through the lateral position detection device and the longitudinal position detection device with the main cylinder on the displacement sensor can accurately know the working state of the upper and lower bolt, to prevent the plug inserted into the unexpected circumstances such as serious consequences .

Selling Units:

Single item

Single package size:

50X30X30 cm

Single gross weight:

100.000 kg

Package Type:

Carton box or wooden case

Picture Example:

Lead Time:

| Quantity(Sets) | 1 - 1000 | >1000 |

| Est. Time(days) | 30 | To be negotiated |

ShanDong UNLE Import and Export Trade Co.,Ltd.

is a manufacturing and trading company of the customized hydraulic system.

Application areas include: Metallurgy, Engineering machinery, Ships, Forging, Machine, Coal, Petroleum, Chemical industry, Scientific research, Military etc,.

ShanDong UNLE Import and Export Trade Co.,Ltd.

is a manufacturing and trading company of the customized hydraulic system.

Application areas include: Metallurgy, Engineering machinery, Ships, Forging, Machine, Coal, Petroleum, Chemical industry, Scientific research, Military etc,.